Description

Product Description

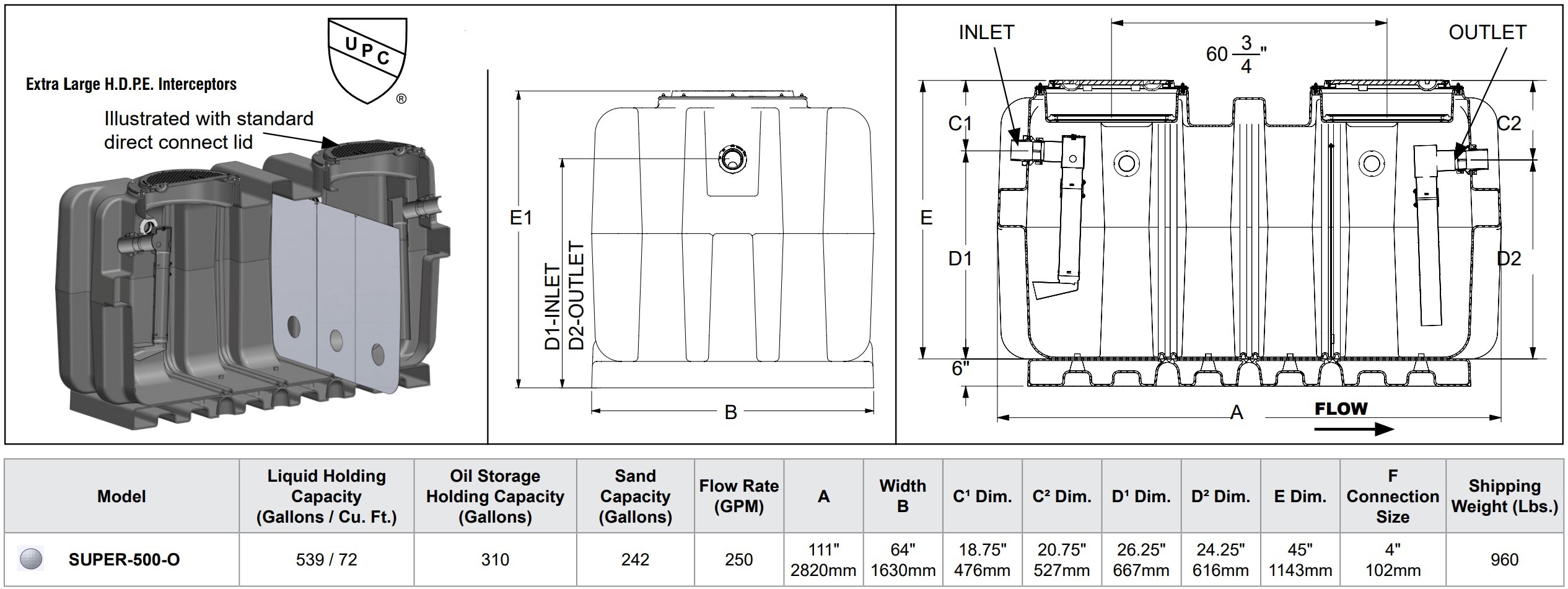

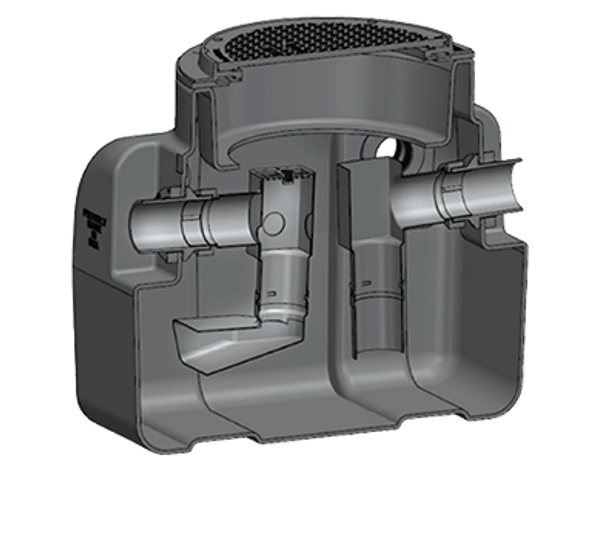

The Drain-Net SUPER-500-O Oil Interceptor is a high-capacity, 500-gallon oil and sediment separation system engineered for demanding commercial and industrial applications. Constructed in the U.S.A. from seamless, rotationally molded High Density Polyethylene (HDPE) with a uniform 3/8" wall thickness, this unit provides long-term durability, corrosion resistance, and superior performance in both above-ground and below-ground installations.

The SUPER-500-O includes a fully adjustable extension system, internal baffles, integral flow control, deep-seal trap, air relief by-pass, dual vent connections, and a stable base for floor-level or in-slab installation. Heavy-duty ductile iron H-20 rated lids, proof-load tested to 40,000 lbs, ensure a water- and gas-tight seal suitable for traffic-rated environments.

Certified to I.A.P.M.O. I.G.C. 183-2016, this interceptor meets stringent requirements for oil separation and environmental protection in commercial facilities.

Key Features & Specs

Capacity & Construction

- 500 U.S. gallon liquid holding capacity

-

Seamless rotational-molded HDPE body

- Material: PE 3135 from Dow 9.39

- Density: 0.939 g/cm³

- Wall thickness: 3/8"

- Limited lifetime warranty

- Made in the U.S.A.

Design & Installation

- Suitable for above or below ground installation

- Includes extension pipe gasket for ADS 24N12 (pipe not included)

- Adjustable lid system for installation flexibility

- Stable base for floor-level installation

- Maximum operating temperature: 150°F

Internal Components

- Internal baffle system

- Integral flow control

- Deep-seal trap (covered by lid)

- Internal air relief by-pass

- Double vent connections (3" I.P.S.) on both sides

- 4" no-hub inlet and outlet connections

- Sample port access included

Lid System

- Ductile iron pickable lids

- H-20 traffic rated

- Proof-load tested to 40,000 lbs

- Water- and gas-tight seal

- Designed to meet AASHTO H-20 loading requirements

Certifications

- Certified to I.A.P.M.O. I.G.C. 183-2016 Standard

Function

Oil interceptors are required in any facility where oil, grease, transmission fluid, or sediments could enter the public sewer system. Typical installation locations include:

- Auto repair shops

- Oil change stations

- Car washes

- Parking garages & lots

- Hydraulic elevator pits

- Manufacturing & testing facilities

- Industrial storage areas

The Drain-Net SUPER-500-O captures oil before it reaches the sewer by separating and retaining floating hydrocarbons in a dedicated chamber. Oil is routed to an adjacent storage tank through an adjustable draw-off system. Regular maintenance ensures peak performance and compliance with local regulations.

Optional Variations

This model is available with multiple optional configurations such as monitoring systems, risers, custom inlet/outlet arrangements, and integrated storage systems.

Contact us for variations such as lid extensions, monitoring packages, alternate connections, or specialized installation accessories.