Can I connect a dishwasher to a grease trap?

It's generally not recommended to connect a commercial dishwasher directly to a grease trap. Dishwashers discharge high-temperature water (often over 140°F / 60°C), which can melt or emulsify grease, allowing it to pass through the grease trap without being captured. This reduces the trap’s effectiveness and can lead to grease buildup in your plumbing or municipal sewer system.

If connecting a dishwasher is necessary, consider using a cool-down or tempering tank between the dishwasher and the grease trap to lower the water temperature. For best performance and longevity of your grease trap, limit connections to sinks, prep areas, and equipment that discharge cooler, grease-laden wastewater.

Always consult local plumbing codes and a licensed professional to ensure proper setup and compliance with regulations. Local plumbing code may require or prohibit a dishwasher discharging into a grease interceptor. Where a dishwashing system is required to discharge into the grease interceptor, it is recommended that it be serviced by a dedicated grease interceptor, separate from the main interceptor.

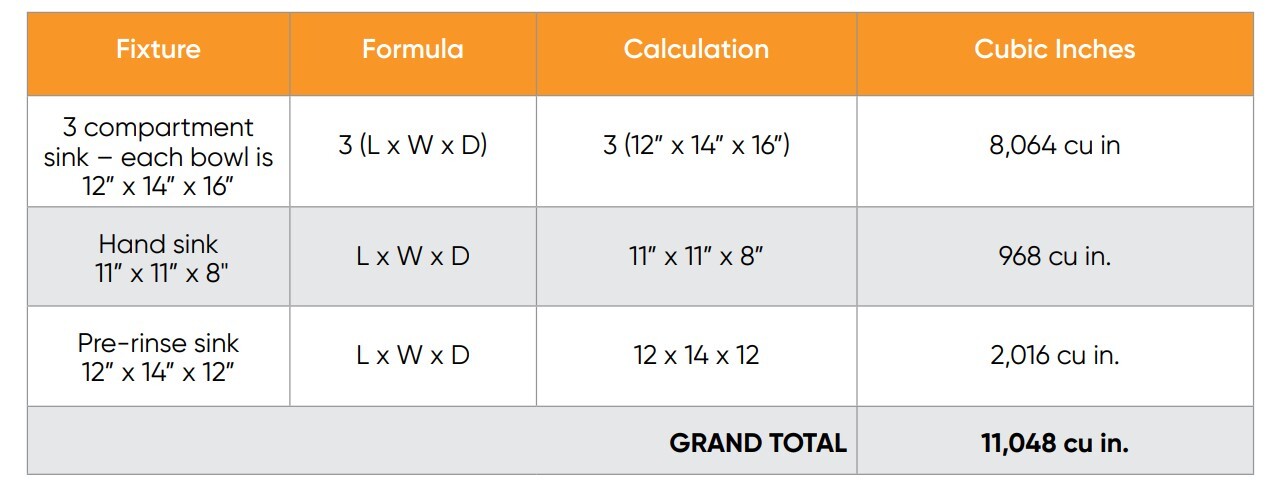

EXAMPLE of calculating GPM needed with a dishwasher:

Consider the following example of a Bar and Grill Restaurant with the following fixtures required to

be connected to the GI:

• 3 compartment sink – each bowl is 12” x 14” x 16”

• Hand sink – 11” x 11” x 8”

• Floor Drains – 4 total

• Dishwasher – Manufacturer rated discharge at 5 GPM

• Pre-rinse sink – 12” x 14” x 12”

STEP 1:

a.- calculate the cubic content of fixtures without a defined discharge rate

B. Calculate the total volume of the sinks by converting total cubic content into gallons:

1 gallon = 231 cu in;

11, 048 cu in/231 cu in/gal= 47.8 gallons

C. Calculate actual drainage load which is 75% of the total volume (Step 2 Value):

47.8 gallons x 75% = 35.85gal.

D. Assign a drain down time.

35.85gal/ 1min DDT = 35.85GPM

E. Add GPM from additional fixtures (i.e. Dishwasher and floor drains) to determine the design flow rate.

35.85 GPM + 5 GPM (dishwasher) + 4( 4 GPM) (floor drains) = 56.85 GPM

F. The minimum size HGI can be determined using the design flow rate in part D. Always round the

design flow rate up to the next available HGI to ensure adequate flow capacity.

For this example an Endural XL 75 GPM hydromechanical grease interceptor would be adequate

(HGI-75) grease capacity 559 lbs